Navigating the fast-paced world of fashion requires a keen sense of timing and a knack for trend prediction. For those in sourcing, that means a constant search for tools and strategies to balance trendiness with practicality, reduce costs, and ensure on-time product delivery. Emerging technologies are now an additional aspect of the sourcing equation. No matter how familiar you are or not with the latest 3D technology, below we’ll walk you through how they could benefit your brand.

Smart Product Selection: Time, Trends, and Practicality

Before getting swept up in the fashion tide du jour, it’s important to align your product choices with the realities of production schedules. Not every trending style will fit into your time constraints due to complexities in design or new materials involved. As a sourcing director, being able to evaluate and select suitable styles that can meet both the demand and production schedule is crucial. This way, your brand stays relevant, and production remains efficient.

Unlock Efficiency with 3D Pattern Making

The fashion industry is witnessing a paradigm shift with the advent of 3D pattern making. Unlike traditional methods, this digital process can save significant time and costs in the design phase. 3D technology enables swift modifications, iterations, and design reviews, helping you finalise patterns before committing to fabric cuts. The result is a streamlined design process and cost savings for your company.

Communication: The 3D Advantage

Working in sourcing, you understand the importance of efficient communication, especially when multiple teams are involved. Here’s where 3D visualisation steps in. This technology provides clear, precise visuals of the finished product, eliminating misunderstandings that can arise from textual or verbal descriptions. In a remote-working era and when suppliers can be thousands of miles away, this tool can facilitate better communication among teams, leading to quicker, more informed decisions.

Streamline Your Supply Chain with 3D Technology

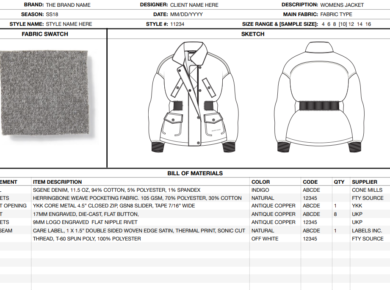

An efficient supply chain is paramount to meet tight product release schedules. With 3D technology, you can visualise fabrics and trims, making selection decisions quicker and more precise. The technology can help you avoid costly mistakes and delays, enhancing your supply chain’s efficiency and, consequently, your product’s time to market.

The Future of Sampling: 3D Visualisation

Traditional sampling and fitting processes can be time-consuming and expensive. With 3D visualisation, you can create photo-realistic garment prototypes and conduct digital fit tests, doing away with the need for physical fittings with models. This shift not only streamlines the approval process but also proves invaluable in a socially distanced work environment.

In summary, incorporating these 3D design and visualisation technologies can revolutionise your work as a sourcing director. They can enable you to align fashion trends with production schedules, streamline team communication, optimise supply chain decisions, and expedite the product approval process. As a trusted partner in your journey, we aim to provide you with resources that empower you to continue excelling in your role and driving value for your organisation. Below we’ve listed a few 3D technology providers to assist you on your journey:

3D technology providers

- Browzwear – browzwear.com – Customers include Superdry, Columbia, Nordstrom, Patagonia, Adidas, Under Armour, and PVH.

- CLO – clo3d.com – Customers include Hugo Boss, Arc’Teryx, VF, Carhartt, Nike, H&M, and Zara.

- Optitex – optitex.com – Customers include M&S, Next, Decathlon, Hugo Boss, Calvin Klein, and Tommy Hilfiger.

- Gerber Technology – https://www.lectra.com/en/products/gerber-accumark-accunest-fashion – Customers include Ralph Lauren, Levi’s, and Under Armour.

- Modelery https://www.modelry.ai/ – Customers include Puma, Made, Fatboy