If you are a business or a brand selling products then product quality and strong supplier relationships should be an important part of your import strategy. Finding a trusted manufacturer who can produce quality products is crucial for you to build and sustain a trustworthy brand.

Consistent product quality is paramount and ensuring you take the necessary precautions and due diligence during the samples stages will make sure you deliver the best quality products for your customers.

What are product samples?

Now for the fun part!

Samples are a good way for a you to test and preview the products from a supplier before you place an order and start mass production. You can request samples at different stages of the development process ensuring tight control over product quality and consistency whilst making sure you get the exact product you’re looking for. It’s like trying before buying.

You can request samples at the beginning of the process as a way to shortlist and select the right supplier. It will give you a chance to see what it’s like working with them and start to work on building your relationship.

You can also request samples during the development phases once you have selected and started to work with one supplier. The samples will be used for you to test the product’s functionality, features and quality during different stages: testing, pre-production stock etc.

Why product samples are important ?

Samples

are very important to all buyers. Often manufacturers and suppliers are based

overseas and in different locations therefore you can’t just pop into the

factory to check on your product’s process. Samples are a way to bridge the

distance gap and for you to check that you are happy with the products.

It is very important to remember that samples are used to check product quality and shouldn’t be used

entirely to judge the supplier’s

quality as a whole. Samples can turn out poor quality for lots of reasons:

insufficient information within the brief, poor quality fabrics and components

used, lack of instructions etc.

Product

fit, sizing and measurements are also really important to check during the

samples stages. Make sure you are happy with every size and measurement for all

your products.

If you are sourcing any products from; clothing, textiles, electronics,

cosmetics the size and measurements of the products will have an effect on

other things such as; product packaging, shipping, packaging to end consumers,

fit. Requesting samples in the development phases will allow you to request the

exact size for your product.

Another important part of requesting samples is that you can use them to get customer feedback, market insights and qualitative research from your end customers. Can you set up a small focus group with your target market to show them the product to identify which features they like, if there are any potential improvements or adjustments that can be made that would improve their experience using your product? This is extremely valuable insights that can help you to start making improvements early on in development phases. It will also help you to stay connected to your customers and help shape the marketing message of your product.

What are the costs of getting samples?

There isn’t a standard cost that you can apply to all product samples however you can expect anything from free samples to 2x, 5x the unit cost per sample.

If you’ve built up a good understanding between yourself and the supplier and work on creating a good relationship then it is likely that you can get some samples for free.

Note: free samples should not be abused and if you are committed to purchasing stock from a supplier then try to make sure the samples you are requesting are the ones you are interested in. Don’t get free samples for the sake of it.

Most people hesitate when it comes to investing in product samples however it’s a very small investment compared to an order of let’s say 1000 units and it turns out that the stock you’ve ordered isn’t right.

The reason why some suppliers request fees for samples is that they would have to start a whole production run only for a few units which would not be cost effective for them. In some cases, they can tag your production along with another customer’s order to help try and recover their costs. But often if the supplier has to provide lots of samples then it would be reasonable for them to request a fee as they don’t have a guarantee that they would win your order.

Some suppliers will reimburse you for the sample fee once you place an order.

It is definitely a balancing act and something that you as a buyer would need to negotiate to help find a suitable solution for both you of.

How do you order and request samples?

- To order samples you will need to shortlist the suppliers you are interested in.

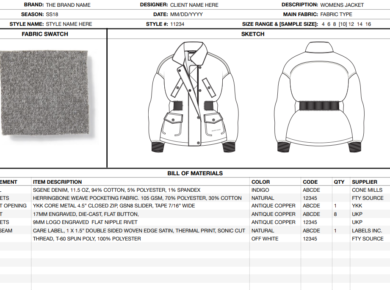

- Send the brief to each supplier detailing the product samples you need: quantity, specifications, features, colour, sizing.

- Depending on your arrangement with the suppliers – you then pay for samples.

- Suppliers ships your initial samples and sends to your home / office address.

- You receive samples and test the product; get feedback and consider any changes you’d like to make.

- It’s always worth sending a quick note to the supplier as a confirmation that you’ve received samples and that you will feedback with your comments once you’ve completed testing. This helps to create good communation and good working relationship with your supplier. Provide a time scale so that the supplier knows when to expect your feedback.

- Once you have completed testing you will need to feedback your comments to the supplier explaining if there are any changes needed. If major changes are needed then this could affect the unit price.

- Further negotiations are probably necessary during these phases so it’s worth spending time talking with your suppliers as much as possible, emails, voice / video calls to build the trust in the relationship. This will allow you to continue to shortlist your suppliers further.

- You may require further samples if there are lots of changes to the original initial samples you received. So, you can repeat the process and progress to the second improved samples.

- Once samples are confirmed you finalise negotiations and decide on your supplier.

If possible, take time during your sample stages, to make your product is the best it can be whilst also using it as an opportunity to build up your relationship with the supplier.

The more time invested at the beginning will save you a lot of time down the road.

For more tips on how to qualify your suppliers click here

Good luck with your search!

Click the link below to find new suppliers to work with to get your free trial of Sourcing Playground’s sourcing database.