Change is afoot in the world of fashion. Many challenges, including global health crises, environmental concerns, and geopolitical unpredictability, are compelling fashion brands to rethink their sourcing and production methods. As the new-age dictates quick turnaround and environmental consciousness redesigns industry operations, a strong blueprint emerges to future-proof sourcing methods.

Given the intricate nuances associated with sourcing makeovers, brands must scrutinize existing strategies and adjust to this shifting arena. Conventional methods often fail to cope with industry transitions, leading to operational bottlenecks and ineffective sourcing plans.

As we move forward, focus on three pivotal sourcing strategies: refine product portfolios, upgrade manufacturing processes, and broaden the supply base across regions.

Refining Product Portfolios: A Fine Balance Between Attraction and Performance

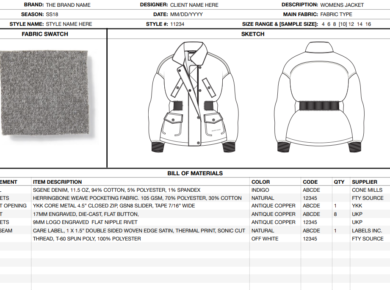

Efficient supply chains begin with the product. The journey towards an efficient supply chain begins with the product. Product intricacy has a direct bearing on manufacturing difficulties, escalating costs and risk factors. By refining their product ranges and classifying their collections based on categories (trendy, seasonal, or staple), companies can enhance profitability and consumer appeal, leading to a lighter load on the supply chain. Pre-setting elements like fabrics, shades, and design patterns can curb production inconsistency and compliance hazards, making the manufacturing process more streamlined. Another dimension to product refinement is creating designs with a value-focused approach, dismantling products to their core functions and gauging their importance from a buyer’s viewpoint. This step allows businesses to highlight high-value elements and remove unnecessary intricacies that weigh down the supply chain.

Upgrading Manufacturing Processes: The Shift Towards Digital

Revamping manufacturing systems is another key aspect of reimagining fashion sourcing. Historically, brands have given their partners free reign to configure their facilities, resulting in a broad range of product mixes that impede focus and productivity.

To counter this, brands should start by categorizing their facilities based on their product repertoire and optimizing their influence. This involves leveraging the power of Industry 4.0 technologies, creating operating models tailored to each facility, and nurturing a spirit of teamwork across the partner ecosystem.

Implementing a model centered on the production line and its team permits the full realization of efficiency. This approach is best enhanced by an investment in digital solutions and nurturing the skills required for ongoing performance enhancement.

Productive collaboration, backed by robust digital capabilities, empowers companies to collectively address issues that impact supply chains, manage disruptions, and harness new technologies. The outcome is a versatile and proficient network of facilities that swiftly adapt to changes and ensure supply consistency.

Diversifying Supply Bases: An Essential Strategy Amidst Uncertainty

In an era of escalating costs and unpredictable global incidents, broadening and diversifying the supply base geographically is more essential than ever. However, modern diversification entails more than just balancing costs and production capacity. Brands must also factor in the availability of raw materials, tariff implications, environmental goals, and compliance with human rights standards.

Near-sourcing or “Nearshoring” whereby companies set up production bases close to the market, is a burgeoning strategy that can slash lead times, mitigate lost demand, and cut down inventory expenses. It also offers environmental benefits by reducing dependence on long-distance transportation, thereby shrinking the product’s carbon footprint.

Managing this diversification requires a data-centric approach, rooted in a solid analytical framework for assessing supplier viability and projecting future scenarios. Comprehensive country development plans, coupled with strategic partnerships with suppliers, government bodies, and industry peers, form the backbone of successful diversification.

However, as brands amplify their sourcing strategies, environmental considerations should remain at the forefront. Brands must use their economic influence to promote sustainable practices in their supply chains, fostering a future that’s resilient, profitable, and ecologically conscious.

The revolution in the fashion industry isn’t confined to profits or productivity; it’s about moulding a strong, sustainable industry that harmonizes with economies, the environment, and the aspirations of tomorrow’s consumers. The journey might be complex, but the potential rewards – robustness, resilience, and ecological responsibility – promise a bright future for the world of fashion.