In this blog we’ll go through a step by step guide on how you can benefit if you “source clothing from manufacturers near me”, countries of interest depending on your location and how to find the right clothing manufacturer that is right for your fashion brand.

Understanding Nearshoring: A Shift in the Fashion Industry

Nearshoring – the practice of transferring a business operation to a nearby country – has increasingly become a significant strategy in the fashion industry. With heightened consumer awareness about sustainability and rapid changes in trends, it’s more critical than ever for fashion brands to keep up. Nearshoring presents an attractive solution by offering proximity, speed, and potentially more ethical practices.

Why Nearshoring Matters: The Strategic Advantage for Fashion Brands

There are several strategic benefits to nearshoring. Firstly, it allows fashion brands to react swiftly to fast-changing trends, an attribute amplified by the digital age. McKinsey’s Apparel CPO Survey 2019 revealed that the majority of chief purchasing officers in the fashion industry believe nearshoring will continue to grow, emphasizing its significance.

Nearshoring also enhances sustainability efforts, which is increasingly important to today’s conscious consumers. Reduced transportation distances mean less carbon footprint, aligning with the environmental benefits highlighted by Sustain Your Style’s report.

Emerging Nearshoring Markets: Hotspots for Fashion Manufacturers

While Asia remains a significant player in manufacturing, nearshoring markets are gaining momentum. Eastern Europe, North Africa, and Central America are some emerging hotspots due to their geographical proximity to major markets, skilled labor, and competitive prices. Data from the World Trade Organization’s World Trade Statistical Review supports this shift.

Geographical location significantly influences a brand’s nearshoring choices. Brands based in different global regions tend to source from specific markets that offer logistical benefits and strategic value.

European Union (EU)-based brands commonly opt for nearshoring within the EU or countries midway between Europe and Asia. Some top locations garnering attention in the fashion industry include:

- Turkey: Turkey boasts a robust textile industry and a strategic geographical location that bridges Europe and Asia, making it a favored destination for nearshoring.

- Italy: Known for its exquisite craftsmanship and high-quality materials, Italy has long been a hotspot for luxury and high-end fashion brands.

- Portugal and Spain: With their skilled labor force and modern infrastructure, Portugal and Spain have become popular choices for nearshoring. They also offer the benefit of being within the EU, ensuring smoother logistics and regulatory compliance.

- Egypt and Morocco: These North African countries offer a blend of cost-competitiveness, skilled labor, and close geographical proximity to Europe, making them emerging nearshoring destinations.

For brands based in the US, nearshoring often implies sourcing from Central and South America. Some of the primary countries in these regions include:

- Mexico: Mexico’s close proximity to the US and extensive free trade agreements make it a compelling choice for nearshoring. It has a strong manufacturing base, particularly in textiles.

- Guatemala, Honduras, and El Salvador: These Central American countries offer competitive labor costs and are geographically closer to the US than Asia, reducing shipping times and costs.

- Peru and Brazil: Known for their high-quality cotton and innovative fabrics, Peru and Brazil offer unique sourcing opportunities. They also have large domestic markets, providing potential for expanded sales.

- Dominican Republic: Offering duty-free and quota-free access to the US market under the Dominican Republic-Central America FTA (CAFTA-DR), the Dominican Republic is an attractive option for nearshoring.

These emerging hotspots in nearshoring offer a blend of skilled labor, competitive costs, and strategic geographical locations. Data from the World Trade Organization’s World Trade Statistical Review supports this shifting dynamic in global fashion sourcing.

The Benefits of Nearshoring: Cost, Quality, and Sustainability

Nearshoring can be cost-effective due to reduced transportation costs, quicker turnaround times, and potential tariff advantages. Quality control is more manageable with closer geographical locations, allowing more regular checks and quicker adjustments. The environmental impact is also reduced due to shorter shipping distances, aligning with the increasing demand for sustainable fashion.

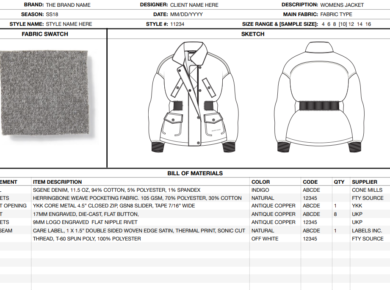

Identifying the Right Manufacturers: Key Criteria for Selection

Selecting a manufacturer is a crucial step in the nearshoring process. Brands should consider factors such as the manufacturer’s experience in the industry, the quality of their products, their ethical practices, and their ability to meet demand. Also, consider their geographical location and the stability of the local political and economic environment.

Choosing the right manufacturer is paramount to your brand’s success. Several key criteria can guide your selection:

Existing Clientele

Analyse the brands and retailers the factory already works with. This can offer insights into the manufacturer’s volume handling capacity, pricing, quality, and compliance norms. If they cater to brands similar to yours, it could indicate a good fit. For instance, a startup might struggle with a factory accustomed to dealing only with large international retailers placing substantial volume orders.

Product Specialization

Depending on your brand’s size and needs, you might prefer a specialized factory or one capable of producing a broad range of products. If your product is technically complex, a factory focusing heavily on similar products may offer better efficiency, quality control, and equipment. Conversely, if you wish to test various products, a multi-product factory might be more beneficial. It allows you to limit the number of suppliers, reduce risk, and build a lasting relationship with your manufacturer. Ultimately, your choice should align with your specific requirements.

Geographical Location

Consider the strategic location of the factory. If your objective is nearshoring, you’ll want to consider shipping lead times, carbon emissions associated with transportation, and quality control. It’s crucial to research the ease of shipping from the manufacturing country to your market. Also, consider potential trade agreements that may offer benefits.

Certifications and Compliance

Check if the factory has the necessary ethical and environmental certifications. Audits can provide a snapshot of a factory’s current standards, while certifications ensure adherence to stringent, ongoing standards. Look for factories with SA8000 and WRAP certification, indicating strong social compliance.

For material sourcing, consider whether you can choose fabrics certified as more sustainable. Factories that can source materials certified by OEKO-TEX, GOTS, BCI, and others could be vital in driving your brand’s sustainability efforts.

The right manufacturer isn’t just about capability—it’s also about fit. Aligning your brand with manufacturers that can meet your ethical, environmental, and quality standards is a crucial step in building a successful fashion brand.

Leveraging Sourcing Playground: Your Ally in Nearshoring

Finding reliable manufacturers can be a daunting task, but Sourcing Playground makes it easier. It provides detailed information about manufacturers, including their ethical standards, quality of work, and customer testimonials. With its intelligent search and comparison tools, you can find the right manufacturer that aligns with your brand values and requirements.

Navigating the complex landscape of global manufacturing can be challenging, but Sourcing Playground transforms it into an efficient, user-friendly experience.

- Peek at the Competition: With Sourcing Playground, you can delve into the sourcing strategies of competitors or similar brands within your market segment. By understanding where they are sourcing from and the products they’re creating with each factory, you can gain valuable insights for your own nearshoring strategy.

- Personalized Search: Sourcing Playground’s advanced explorer tool allows you to input your unique criteria and swiftly generates a curated list of factories that meet your specific needs. This custom search can help you pinpoint suitable manufacturers in a fraction of the time it might traditionally take.

- Country Specific Searches: Interested in a specific nearshoring market, like Turkey? Sourcing Playground allows you to filter by country and product type to reveal the top manufacturers and suppliers in your target market. This feature can help you make more informed decisions and identify promising opportunities.

If you’re curious about how Sourcing Playground can simplify your nearshoring process, why not experience it first-hand? Sign up for a free 7-day trial here and unlock your brand’s nearshoring potential today.

Successful Case Studies: Brands Winning with Nearshoring

One of the most compelling ways to understand the benefits of nearshoring is through real-world examples. Sourcing Playground offers an array of case studies showcasing successful nearshoring strategies, including an inspiring example from a major UK retailer.

Nearshoring Success: A Major UK Retailers Strategic Shift

Facing the challenge of making informed strategic sourcing decisions, this UK retailer, with over $10B in revenue, sought to explore new markets and potentially reduce lead times through nearshoring.

Leveraging Sourcing Playground’s competitor tracking feature, they were able to regularly receive insights into the supply chains of their competitors, which informed their decision-making process. With this data, they gained the confidence to shift towards nearshoring, recognizing its strategic advantages and its adoption by similar brands and competitors.

The decision to nearshore has since provided significant benefits for the retailer:

- Reduced Lead Times: By sourcing from nearshore markets, the retailer was able to significantly reduce lead times and increase flexibility within its supply chains.

- Informed Decision Making: With access to up-to-date market intelligence, their sourcing teams could anticipate market movements and secure production space with top suppliers ahead of the competition.

- Risk Mitigation: The insights provided by Sourcing Playground helped the retailer identify and avoid potential risks, inexperienced suppliers, and costly mistakes, thereby minimizing disruptions in their supply chains.

- Competitive Advantage: By observing their competitors’ strategic sourcing initiatives, the retailer gained the confidence to enter a new market, reaping the benefits of nearshoring’s speed and flexibility.

This UK retailer’s successful nearshoring experience serves as an inspiring testament to the strategic value and tangible benefits of this sourcing model. With Sourcing Playground, your brand, too, can tap into these opportunities and reshape its sourcing strategies for the better.

In conclusion, nearshoring presents a significant opportunity for fashion brands. It’s a strategy that balances cost, quality, and sustainability, whilst allowing brands to stay agile in a fast-paced industry. Whether you’re an emerging designer or an established brand, considering nearshoring could be a strategic move for your manufacturing needs.