As someone who has been involved in sourcing and production management, both as an executive for a branded apparel distributor and as a consultant, for close to twenty years, I am often surprised at the lack of supplier management ability amongst buyers.

Many simply place an order, and then essentially forget about it until a week before delivery. Sure, there will be some emails back and forth between the buyer and supplier, but often nothing of real consequence, and usually if the buyer asks questions, they are the wrong ones, or at least the easy ones for a supplier to answer.

In fact, I can say without hesitation, that many of the problems that arise with orders, or problems with relationships between a buyer and a supplier, are not the supplier’s fault, as the majority of buyers tend to believe.

As buyers we are often in an echo chamber, where everything is the supplier’s fault. These problems are usually the result of poor or non-existent supplier management, on the buyer’s part. What’s even more worrying, is that this applies not only to new buyers, where it can be expected, but also with seasoned buyers.

In my experience as a consultant, the main reason for this, is that many buyers simply see supplier management as a cost, without any real value.

Often, I do phone interviews with potential clients, and I pick up relatively quickly that they are looking for a crash course in supplier management. After our chat I usually wait a few days and send a follow up mail. The reply is usually along the lines of,

“We would love to have you on board, as we can see you are highly experienced, but we do not have the budget to hire someone right now”.

I am often tempted to ask the obvious question. “So why are you advertising for the position?” But I bite my tongue. I also come across situations where I recommend suppliers I have worked with successfully for years, to new buyers. In many of these situations, things often fall apart relatively quickly. Generally, in both mentioned situations, I will get a frantic mail from the buyer.

In the first scenario, they are looking for help as their order is going down the tubes. In the second, usually to blame me for recommending a bad supplier.

In some

cases, I offer to assist, but on the condition that I get access to all

previous email exchanges between the two parties.

And this is usually where I see all the problems.

Some of the most apparent are;

- Unrealistic expectations

- Trying to force issues

- No contingencies

- Information coming through in bits and pieces

- Constant changes

- Inability to read between the lines

- Lack of business knowledge

- Lack of gut feel

- Not listening to advice

So, let’s look at each of the above points one by one.

1. Unrealistic expectations

Many buyers suffer from this affliction, and it is often fed by suppliers.

I can understand suppliers feeding this (they do not want to lose business, so essentially commit to anything to secure the order), but cannot really understand it from a buyer’s point of view. In my opinion, it is simply the lack or reluctance to critically and logically look at things.

In some cases, no real thinking at all.

A typical example is lead times. I see this daily on Sourcing Playground, as well as on the other big sourcing platforms

In most cases, we are looking at a lead time of 60 to 75 days for most bulk orders, if done properly and all boxes are ticked.

I often come across buyers looking for lead times of less than a month. Today I came across a buyer wanting to develop two products and manufacture them in 21 days.

In most cases the supplier will come back with a compromise of around 45 days, which is usually just as unrealistic.

But the supplier’s intention is to confirm the order and then deliver late, knowing full well they will be delivering late.

Essentially feeding the buyers unrealistic expectations.

Then when the supplier tells the buyer that they need a 3 week extension, the problems start, and the relationship falls to pieces.

Sound familiar?

2. Trying to force issues

Very often I come across buyers who have specific requirements, which I know they will not achieve.

As an example, I recently had a buyer approach me after their supplier sent them incorrect samples, and after an argument they dropped the supplier.

They needed samples made urgently for a photo shoot that they claimed the photo studio was already booked and they could not change the date.

The supplier I referred them to told them this would be extremely difficult to achieve (I told them it would be impossible), but they essentially forced the supplier to give them a date, which was missed.

The relationship fell apart.

Granted, the supplier should have refused outright, but in today’s tough market this is not going to happen.

That being said, the buyer should have listened to my objective statement. This statement was backed up with a timeline.

3. No contingencies

One of the most important areas buyers often miss, is not having a backup plan.

They find a factory, everything looks good, they get samples, and then make the mistake of thinking the order will go smoothly.

It often doesn’t.

Therefore, it is critical to have a backup supplier, that you can switch to if things fall apart with your primary supplier.

Just like the above example of unrealistic expectations, I am often contacted by buyers because their supplier let them down at the last moment, and they desperately need a new factory.

Ensure you make contingencies for everything.

4. Information coming through in bits and pieces

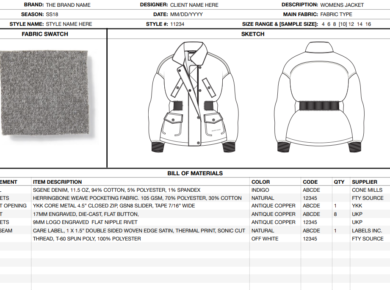

I am often amazed at the number of buyers that refuse to invest in a proper technical package, or even buy a technical package template online for $15.

Make no mistake.

Without a proper technical package, there is a 90% chance your order will be incorrect, and this is entirely the buyer’s fault.

There is no excuse for the lack of a decent technical package.

Without the proper information presented correctly, buyers leave room for assumptions.

You know what they say about assumptions being the mother of?

Often buyers try to describe their entire product in an email, or multiple emails, with no visual reference.

Suppliers are usually very visual. A picture does speak a 1 000 words in this case.

Also, many suppliers are not native English speakers, so there is the “lost in translation risk”.

This doesn’t work.

Here is an actual example, where the buyer simply sent photos of similar product, and tried to explain the rest of it to the supplier;

“Kindly find attached the style pictures :

1st style

W34xL40cm

Depth : 9cm

Handles : 60x3cm

2nd style :

W40xL27cm

Depth : 12cm

Handles : 60x3cm

I would like a quote for both of them please.

Also, we would like to make 300 baby T-shirts made of 100% Oeko Tex and GOTS Cotton with satin embroidery and 2 Oeko Tex snaps. 140gsm.

We would like to make a “marinière” such as the picture attached but with the breastfeeding opening.

I really want something similar to the fabric they used ( color : ecru and navy, stripes starting on the breasts level ) I think, it’s a thicker cotton, maybe Rachel cotton or French Terry cotton, what do you think? If you can do 300 pcs of that with the 3 golden buttons. we would love to have a quote. Please send us a quote and depending on our budget, we will let you know what we will be ordering. Thanks,”

No technical information at all.

This type of email chain continued for weeks. There were numerous changes made as well, also with no visual reference. How does a supplier quote on embroidery they have never seen? Or “3 golden buttons”? But the supplier is also to blame.

They should have stopped the buyer right at the beginning and demanded a technical package, as well as explaining why this is crucial. This relates directly to points 1 and 2, above.

5. Constant changes

Be pretty sure of your designs prior to sending your technical packages to suppliers.

Another risk factor in supplier management, is constantly changing things.

For example, a buyer is not certain of the final design of a print, and the supplier then prints a sample. The buyer decides this is not the “look” they want, so they ask for another technique to be used. Now, I am not saying things cannot be changed. It is constant changes that cause a problem.

You should be at least 90% sure of what you want prior to sampling with a supplier.

But, if you only have a broad idea, then you will have problems. It gets very confusing for both the supplier and the buyer, and mistakes can be made. It is also very irritating for a supplier when they do something exactly to a buyer’s requirements, and then the buyer decides to change this. Especially if it is done multiple times in the course of an order.

It costs the supplier time and money, and as mentioned, there is a massive risk for the buyer due to the amount of conflicting information that is flying around.

6. Inability to read between the lines

Anyone that has done business in China, soon realises that Chinese suppliers are often very indirect. They have the tendency to talk around a subject, which involves a lot of innuendo. This is a cultural issue, so maybe the heading here should be “Understanding business culture in different countries.”

Instead of saying “No” outright, they might say something is “Very difficult” or something similar. Essentially, they are saying “No”.

Buyers often do not realize this and try to overcome the “difficulty”. This usually ends up going nowhere, and wastes time and money. It is better to suggest alternatives. Suppliers will be more open to this, as when they mention “difficulty”, it could also mean they are looking for some type of compromise.

So, learn to read between the lines!

7. Lack of business knowledge

I often come across brilliant designers and creative people that are eager to start their own brand. More often then not, despite being excellent on the design side, they lack the required business knowledge, which often leads to major problems.

They do not know about INCOTERMS, payment terms, shipping, inspection requirements, quality control methods, etc. Needless to say, this knowledge is critical.

They often rely on their supplier to organise or suggest business terms to them.

This usually results in business terms weighed heavily in the supplier’s favor.

And I certainly do not blame the supplier for this. Any sane business person would look to weigh a deal in their favor, and in Latin, Ceteris Paribas.

Recently I dealt with a buyer, who paid for their entire order upfront.

The supplier simply told them this was the norm and the buyer accepted that.

The order is now over a month late, and many of the items were Christmas product.

The buyer has no leverage over the supplier to force them to ship the goods, and the supplier has been paid.

8. Lack of gut feel

Although this is hardly objective, sometimes you need to “go with your gut”.

At times things just don’t feel right, and they often aren’t.

Your subconscious picks up signs that you are not even aware of on a conscious level!

Gut feel is essentially the same as intuition.

And there have been studies showing that “Gut Feel” is actually a process and should be taken into account, as it is a logical process (as illogical as it sounds).

Check out this article! It is a bit of a read, but very interesting.

Simply put, “Gut feel” is a predictive thought process, based on knowledge and past experience, that is able to adjust to new input.

Its not witchcraft or illogical.

9. Not listening to advice

Believe it or not there are a lot of people out there willing to give practical advice on supplier management, as well as plenty of available resources.

Linkedin is a great resource.

There are many articles and posts dealing with this topic. Quora is another.

Even a simple Google search, will uncover valuable resources.

As a prime example, I will suggest INCOTERMS or payment terms to buyers on occasion.

Some listen and some do not.

It is up to you, as a buyer, to decide what advice to follow and what to ignore.

However, listen to all advice and make an informed decision.

And that’s it for a quick introduction of what’s important in managing suppliers to ensure the best sourcing experience possible.

It requires some work on the buyer’s side, but will provide new buyers with a valuable learning experience.

Happy Sourcing and Happy New Year from all of us at Sourcing Playground!