At Sourcing Playground, we commonly get asked a lot of questions from buyers along the following lines:

- “How do I know if a particular factory is good?”

- “How do I know if a factory can make my product?”

- “How do I know if a factory can achieve my required quality level?”

- “How do I know if a factory is actually a factory and not a trading company or agent pretending to be a factory (very common)?”

The simple answer is that all of these questions, and more, can be addressed with proper factory verification or evaluation.

The problem is that many buyers do not know how to properly verify and evaluate a factory. The next question that comes up from many buyers, is pretty obvious.

How do you verify and evaluate a factory?

Luckily for these buyers, there are a number of methods that can be used. These can be used individually or in combination. Obviously in combination is safer.

Third Party Factory Inspections/Audits.

Many third-party inspection agencies, such as Intertek, Asia Quality Focus, TUV, Bureau Veritas, and SGS, (as well as many lesser known ones) will audit a factory for a fee.

This fee depends on a number of factors, which are beyond the scope of this post, but a general report will consist of a number of sections, such as a general overview with a score, a factory profile, workflow and organisation charts, information on production lines and their capacity, quality procedures, factory facilities and machinery, amongst others.

They will then send you a report with photos. These reports often have a scoring system that gives the buyer easily accessible information at a glance. Any areas of concern will be noted in the report, and receive a low score.

Bear in mind that these reports can run into 30 or 40 pages, so we have only covered the tip of the iceberg. For more details, you can check the Asia Quality Focus website. A sample report can be requested for your information.

This method has obvious advantages, such as experienced and certified inspectors as well as objectivity.

However, there are two issues with audits. Firstly, if you want to inspect multiple factories, it can get really expensive. Secondly, an audit is simply a snapshot in time.

Things might change tomorrow. A factory might have “borrowed” a machine from a friend’s factory, just to pass the audit. This is also fairly common.

Self-Verification

With some experience, and a bit of common sense, you can self-verify your supplier.

It will not be as in depth as an audit from a third-party inspection agency, but when you are dealing with multiple factories, the cost of the above-mentioned audits, can be ridiculously high, and usually unaffordable for the average buyer. For massive buyers, such as Nike and Primark, this is not really an issue!

For most buyers, the order process starts off with reaching out to a few factories to get quotes for their products. Sound familiar?

The next question would be how to self-verify?

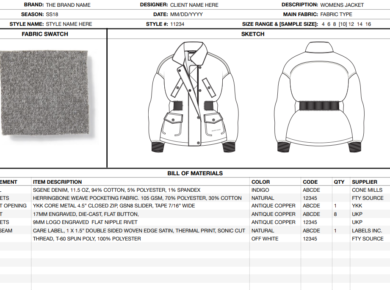

The first thing would be to begin with two documents. you would prepare yourself and mail to your potential suppliers:

- A company introduction document, which outlines your non-negotiable business terms, quality requirements, expected lead times, sampling requirements, etc.

- A factory evaluation document the factory needs to fill in.

These two documents are important for a number of reasons.

- If a factory cannot meet your basic business terms contained in your company introduction document, there is no use wasting time discussing anything further. For example, if you only pay by letter of credit, rather find out that a factory does not accept letter of credit payments at the beginning.

- Many new buyers will spend hours and hours with a factory, possibly even visit, and when it comes time to place the order, the factory will state they cannot accept one or another of the buyer’s terms. Rather find this out at the beginning. It will save you money and time.

- The factory evaluation form is obviously not as detailed as a professional third party audit, but it should ask for basic info such as business registration and licence documents, a list of machinery, number of workers, number of production lines, QC department details, sample department details, photos of the factory (internally and externally), whether the factory has the right to export or must export through a trading company, etc. It will tell you if the factory can meet your needs.

- These two documents require input from the factory, and will give insight into their ability to follow simple instructions, how long it takes them to respond, and to see if they ask the “right” questions. Remember. You are not only interested if a factory can make a product. You are also interested to see if they are going to be difficult or easy to manage. If a factory does not confirm they have received your mail, this is a problem, as you will have to follow up. If they say they will return the evaluation form on a specific date, and do not, this is a problem. Especially if they do not inform you of this. Again, you will need to follow up with them.

- They will let you know if the factory has competent English-speaking staff. Whether you like it or not, English is the international business language.

If a supplier cannot read a document properly, fill in a document properly, follow basic instructions, and miss simple deadlines, they are going to be a problem. Period.

With self-verification, you should still visit the factory prior to doing business.

We cannot stress the importance of this.

To be cost effective, set up a trip to see the maximum number of potential suppliers. Take the factory evaluation form and photos to each factory. It has been known for buyers to be taken to a different factory to the one they have been given information on in the factory evaluation form.

This usually occurs when a trading company or agent, tries to pass themselves off as a direct factory.

Do not be afraid to ask questions. Often on a factory tour, there will be people other than your contact accompanying you. Ask who they are. Often the factory owner will accompany you on your tour, but might simply pass themselves off as a low level manager. They do this to check your experience as a buyer. If they feel you are inexperienced, expect above market prices, so it is always good to act as if you have a lot of experience in factory tours. Walk the lines, look at product, check out the operators and the machines. Just do not look like the proverbial deer in the headlights!

We hope this article gives you some practical insight into how to verify a factory.

Remember, you can never fully eliminate risk. Your goal should always be to reduce any risk as much as possible. Supplier verification goes a long way towards this goal.

To find out more ways you can reduce risk in supplier sourcing check out our latest blog here:

Happy Sourcing, and remember. All of us at Sourcing Playground want you to have the best sourcing experience possible!