There is always a relatively large element of risk when sourcing a new supplier for your product. While this risk can never be fully eliminated, it can be reduced considerably by the process you use in sourcing a new supplier.

Make no mistake, sourcing a new supplier is a process, with a number of specific steps to follow. If you follow these relatively simple steps, we believe you can reduce your risk to the lowest possible level. Keep in mind these steps are not always linear, but often run congruently. Communication is a good example of a congruent process. There is more on this in the below sections.

The first step in the process is identifying the risks. Once these are identified, we can look at the ways of reducing them.

Risks associated with using a new supplier

- Misunderstanding of your requirements. The new supplier does not fully understand your requirements. In many cases, this is only apparent far down the line, after you place your order and the supplier is already working on your product.

- Delays in meeting deadlines. Any delay in meeting a specific deadline, i.e. sending a component for approval has knock on effects.

- Delays in delivery. It is very common for suppliers to deliver late. A week or so is usually not an issue, as most buyers build in some time for late deliveries. If they don’t, they should. Always ensure you build in some time for late delivery (but never let your supplier know. As far as they are concerned the confirmed delivery date is set in stone!).

- Quality issues. The final product has quality issues, and does not pass the required tests. These can be minor, and make no real material difference to the product, or critical, where the product is non-usable.

- Compliance issues. This is separate from quality issues. Most countries have a list of requirements that a product must meet to be sold in that country. For example, the wording and font size of suffocation warnings on plastic packaging. If you are buying wholesale, and are planning to sell on to a retailer, be aware that many retailers have their own compliance requirements.

- Relationship issues. Relationships between buyers and suppliers fall apart extremely often. There are numerous reasons for this, that range from culture to the egos of the parties involved.

- Synergy issues. Does the supplier have the ability to produce your order as well as any sampling required? Is there a very high level of synergy between your requirements and your supplier’s ability

I am sure you can think of a few other risks associated with sourcing a new supplier, but the above are probably the most critical.

As mentioned, sourcing a new supplier is a definite process, and if followed, all risks are significantly reduced. So, let’s get onto the process!

1. Pre-vetting suppliers

When you are searching for a new supplier, and put a Request For Quotation (RFQ) on any of the various B2B platforms, you will get plenty of responses. At least between 10 and 20 per platform. In most cases, the amount of responses will be unmanageable. So, these suppliers need to be pre-vetted. How do you do this? Fortunately, the answer is pretty simple.

When you submit an RFQ, you will be prompted to state certain requirements. For example, incoterms, payment terms, etc. You are also required to give a brief description of your requirements. Always ensure you include your order quantity, whether you are willing to work with traders or agents, any certification required, and your desired supplier location. Basically, as much objective information as possible. When suppliers start responding, ignore all the ones that do not meet your objective requirements. For example, if you state your payment term as a letter of credit, ignore those suppliers which state their terms as TT (telegraphic transfer). It is clear that they have either not read your RFQ properly, or are simply ignoring your requirements. Both are obvious red flags. If you specifically mention you only want to deal directly with factories, ignore those respondents which are trading companies. For many new buyers, there is a tendency to engage with such suppliers. Maybe you email them back, restating your terms. Don’t. If a supplier cannot be bothered to read your RFQ in detail, or ignores certain requirements, what will they ignore if you place an order with them? Many B2B sites give an option for refusing a quotation. Use it.

2. Dealing with suppliers that have passed the pre-vetting stage.

By now you should have a manageable list of potential suppliers. However, you will still need to narrow this down even further. One simple way to do this, is by setting each supplier a simple task, and seeing if they complete this task correctly and on time.

Many seasoned buyers will send a potential supplier a form to fill in with information about their factory. This usually relates to machines, monthly capacity, business licences, and photos of specific areas of the factory. These buyers usually give a timeframe for the supply of this information. If the supplier fills the form in incorrectly, omits information without an explanation, or misses the deadline given without telling the buyer this prior to the deadline being missed, they cross these suppliers off their list. If they can’t perform a simple task, how do they perform a complicated one?

I don’t know how many of you use LinkedIn? If you do have a look at posts where a recruiter posts a job. These posts are very common. The recruiter usually gives a simple instruction. For example, “please send your CV to a specific email address”. Then scroll down the comments section, and see how many applicants simply comment “Please see my profile”. Clearly these applicants have not bothered to read the post, and if they have, do not understand / not willing to follow a simple instruction. Would you hire any of these applicants? Probably not. The same goes for potential suppliers.

3. Communication.

The above two vetting processes, both have a very strong focus on communication. Simply put. If a potential supplier cannot respond in a correct and timely manner, you can cross them off your list. Experience shows this will not improve. If communication starts off bad, it will only get worse. This poor communication will manifest itself the most if any problems arise during the production process. In this day and age, communication is instant. So, no one has any excuses anymore for poor communication.

Also pay attention to see if all your questions are answered in all communication.

Tone of communication is important.

Try to determine if the supplier really wants to do business with you, or is just going through the motions. I am sure many buyers have been in a situation, where they place an order, and then get let down by their supplier because the supplier received a bigger and more lucrative order. It is common for suppliers to complain about a buyer’s small order quantity and prices, and buyers often write this off to the usual supplier behaviour. However, there are many cases when this is more than simply normal supplier behaviour. They do not really want to do your order, but they have unused capacity. As soon as something better comes along, your order will take a back seat.

This is often very difficult to determine. Remember, that we previously mentioned seasoned buyers often ask for factory photos? These photos can tell you a lot. For example, if the production area is not busy, or machines are idle, it is often a clear indication of excess capacity.

Ask your potential suppliers when their busy periods are (This often differs from country to country, and industry to industry). Can you place your order during their “slow” season?

Also, if you have five potential suppliers, and four give consistent answers regarding their busy periods, while the fifth supplier gives an inconsistent answer, it is likely that there is an issue with the fifth supplier. As an example, if the five suppliers send you photos, and it is their busy season, their production area should be full. If one of the suppliers has a relatively empty production area, this is another red flag. There is no real excuse for this, other than the factory does not have orders. Then you need to ask yourself why it doesn’t have orders.

Another thing that you should be careful of is lack of questions from a supplier. This is critical for two reasons. One, they are assuming certain things, and two, they think asking questions will somehow make them look bad (As if they do not know their business). In fact, the more questions asked by a supplier the better (within reason). It shows they have fully checked your requirements, but are unsure of certain aspects. There will always be uncertainty about certain elements. This is fine. Asking for clarity is a good start. It also shows that they are confident enough to ask questions, without seeing this as a negative.

Basically, a supplier with no questions might be worth avoiding. There are always questions. No matter how good the information is you send to a supplier, there will always be something missing from the supplier’s viewpoint.

4. Supplier size versus order size.

It is also important to look at the size of the factory when determining risk. If your order is small, you are better going with a smaller supplier. If your order is large, you are better off with a bigger supplier. A small supplier may not have the capacity to deal with large orders. A big supplier essentially needs larger orders to meet costs and profit requirements. When you are looking at potential suppliers, pay particular attention to the size of their factory. This is best indicated by the number of machines or workers. If this information is not easily apparent, ask for it. If you are ordering 300 units of an item, a 2000-worker factory is far too big. You are probably better off with a 50-worker factory.

If you have sampling requirements, you need to get information regarding the suppliers sampling capacity. Every supplier should have a distinctly separate sampling room for manufacturing buyer’s samples. If a buyer has a large sampling requirement, this sampling room needs to be large enough to handle this. This should be discussed with the supplier. Keep in mind, that the supplier will have other buyers that they need to sample for. Try to determine the sampling room’s workload.

5. Quotes.

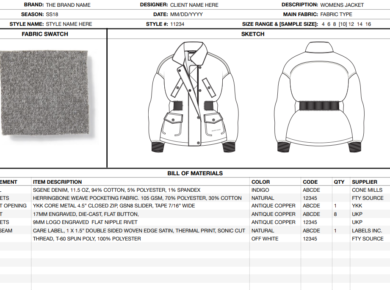

Once you have narrowed down your list of potential suppliers, taking the above points into account, let them quote on your product. It is critical here to ensure that you provide complete and accurate information to the suppliers. You need to ensure this. The supplier can only quote on what you provide. If your information is incorrect or incomplete, the quote will not be accurate.

Once you have quotes in, keep the following in mind.

The quotes should be within a similar price range. If you have five suppliers, and four quote between US $1.15 and US $1.30, and the fifth comes in at US $3.10, you can be sure the fifth supplier made a mistake. You need to question this.

The same applies for quotes that seem too low. This is a different beast, though. Be very careful here. As a buyer you will be drawn to the lowest cost. Do this at your peril. If something is too good to be true, it usually is. Say the fifth supplier came in at US $ 0.80, you will probably think they are the most honest supplier. This is a very dangerous assumption, and has led to many buyers losing a lot of money and time. A more logical explanation is that the supplier has made a mistake in their costing, and / or the services they offer are less than the other suppliers. You need to question all these outlying prices, whether too high or too low.

6. References

It is always worth asking potential suppliers for contact details of other previous or current buyers, in order to get a reference. The problem here is that most suppliers are loath to give these details. They will come up with excuses such as confidentiality, non-disclosure agreements, etc.

In most cases these are just excuses not to supply the information!

They do not want buyers to contact other buyers for various reasons. Besides the obvious one, where one buyer tells the potential buyer of problems they might have encountered, they really do not want buyers discussing prices paid. If the supplier quoted you a much higher price for similar items than the buyer / buyers you have spoken to, you are not going to be happy. The opposite also applies. Your prices are lower than the other buyer / buyers. They are not going to be happy.

However, some suppliers will give you references, but this is the exception. But potential suppliers tend to be pretty open about brands they have worked on before. They are also usually very open about the country the brand is in. So, if you are willing to do some research, it is often possible to track previous buyers down. This can take some time, but is often worth it.

It is also important to keep in mind that there are two sides to every story, so if a buyer gives a poor reference, discuss this with the supplier to hear their side of the story. It also sends a powerful message to the supplier that you are strong on your diligence checks.

However, it is better to be on the side of caution, and steer clear of suppliers with bad references, especially if there are a few bad references.

7. Experience in doing business in the country of import.

At the beginning of this article, when we looked at risk factors, compliance (regulation) issues were mentioned as a risk. Therefore, it is important that any supplier you choose is experienced in exporting to your country or country of import.

Simply put, if a supplier has never exported a product to the country in question before, it is a risk to do business with them. Everything might be smooth until the goods are stopped at customs, because of a compliance issue.

Possibly a chemical was used in the production process that is disallowed. Often the supplier needs to provide documentation showing compliance with the rules regarding import into a specific country. If the supplier has no experience doing orders for the country in question, there is the risk they do not know the rules and regulations.

8. Experience in similar products.

It is also important to determine whether the supplier is experienced in items very similar to yours. If we use the apparel industry as an example, just because a factory makes great T-shirts, does not mean it makes great hooded long sleeve sweaters. The machines needed often differ, as well as the basic patterns, and skills.

Make sure your potential supplier can show evidence of very similar product to yours.

9. Ensure you give yourself enough time to source the right supplier.

Always try to give yourself enough time to source. If you are under time pressure to find a supplier as soon as possible, the higher the chances of choosing the “wrong” supplier.

Give yourself at least two to three weeks to finalise your supplier.

As you can see from the above, there may be a lot of back and forth communication between potential suppliers and yourself. Sometimes information takes time to gather. There can be a lot of questions from either the suppliers or yourself. There will likely be large time differences. Ideally you need enough time to ensure all your questions are answered in a satisfactory way, and you are confident in the ability of your chosen supplier. This does not happen overnight. We cannot stress the importance of time. Rushed decisions are often wrong decision, as not all the variables are thought out and taken into account.

And that’s it!

We really hope the above is useful in your sourcing of suppliers. At Sourcing Playground, we want our buyers to have the best possible sourcing experience possible. The above points should definitely add value to your sourcing. And adding value is what we are all about.