Optimising supply chain operations is crucial for maintaining a competitive edge. One of the most powerful tools at a company’s disposal is spend analysis. This comprehensive approach to examining procurement data can reveal hidden costs, inefficiencies, and opportunities for improvement throughout the supply chain. Let’s look into the intricacies of spend analysis and explore how it can transform your supply chain management.

Understanding Spend Analysis

Spend analysis is a systematic process of collecting, cleansing, classifying, and analysing expenditure data to reduce procurement costs, improve efficiency, and monitor compliance. It provides a clear picture of an organisation’s spending patterns, helping decision-makers identify areas for cost reduction and process improvement.

The Process of Conducting a Spend Analysis

- Data Collection: Gather relevant data from various sources, including ERP systems, purchase orders, invoices, and contracts.

- Data Cleansing: Standardise and validate the collected data, removing duplicates and correcting errors.

- Data Classification: Categorise spend data into meaningful groups, such as supplier, product category, or business unit.

- Data Analysis: Examine the classified data to identify trends, patterns, and opportunities for improvement.

- Strategy Development: Based on the analysis, develop and implement strategies to optimise spending and improve supply chain efficiency.

Key Benefits of Spend Analysis

- Cost Reduction: Identify opportunities to negotiate better terms with suppliers, consolidate purchases, or find alternative sources.

- Risk Mitigation: Uncover dependencies on single suppliers and develop strategies to diversify the supplier base.

- Improved Supplier Management: Gain insights into supplier performance and identify strategic partners.

- Enhanced Compliance: Ensure adherence to contractual terms and company policies.

- Operational Efficiency: Streamline procurement processes and reduce administrative overhead.

Challenges in Conducting Spend Analysis

Despite its benefits, many procurement and supply chain teams face significant challenges when conducting spend analysis. Often they are missing vital information to help drive and inform strategic decisions:

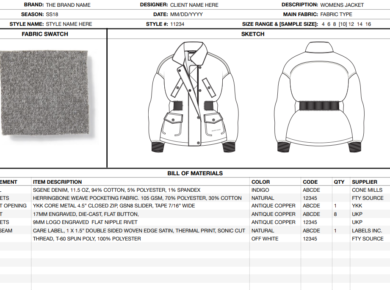

Limited Supplier Visibility: Many organisations lack comprehensive information about alternative suppliers for specific SKUs or bill of materials (BOMs).

Geographical Insights: Teams often struggle to visualise supplier locations in relation to their own facilities or customers, hindering efforts to optimise logistics.

Sole Sourcing Risks: Without proper analysis, companies may not be aware of products where they depend on a single supplier.

Pricing Comparisons: Difficulties in comparing supplier pricing for specific raw materials across the supply base can impede negotiations.

Product and Packaging Visibility: Large organisations may struggle to link raw materials, packaging and SKUs, missing opportunities for standardisation.

- Identifying cost-reduction opportunities with more cost-effective suppliers

- Optimising production locations relative to demand

- Responding flexibly to supply disruptions

- Understanding and mitigating supplier dependencies

Unlocking Value Through Effective Spend Analysis

Despite these challenges, the potential value of comprehensive spend analysis is immense. By overcoming data silos and implementing advanced analytics tools, organisations can:

- Achieve Significant Cost Savings: Identify and eliminate unnecessary expenses, negotiate better contracts, and optimise supplier relationships.

- Enhance Supply Chain Resilience: Diversify the supplier base and develop contingency plans for potential disruptions.

- Improve Decision-Making: Provide leadership with data-driven insights to inform strategic sourcing decisions.

- Drive Innovation: Identify opportunities for product or process improvements through collaboration with key suppliers.

- Boost Operational Efficiency: Streamline procurement processes, reduce cycle times, and improve overall supply chain performance.

Implementing Effective Spend Analysis

To unlock these benefits, organisations should consider the following steps:

- Invest in Advanced Analytics Tools: Implement software that can integrate data from multiple sources and provide multi-dimensional analysis capabilities.

- Develop a Centralised Data Repository: Create a single source of truth for all spend-related data.

- Foster Cross-Functional Collaboration: Encourage cooperation between procurement, finance, and operations teams to gain a holistic view of spend.

- Implement Continuous Monitoring: Regularly update and analyse spend data to identify trends and opportunities in real-time.

- Invest in Training: Ensure that procurement and supply chain teams have the skills necessary to conduct effective spend analysis and interpret the results.

Conclusion

By overcoming data challenges and implementing robust spend analysis practices, organisations can unlock significant value, reduce costs, and build more resilient and efficient supply chains. Once the right data infrastructure is in place, organisations can leverage advanced analytics and artificial intelligence to uncover even deeper insights and identify previously hidden opportunities for savings. This combination of comprehensive data and intelligent analysis empowers businesses to make data-driven decisions that can transform their supply chain operations. As we move forward, those who master the art and science of spend analysis and harness the power of AI-driven insights will be well-positioned to thrive in an increasingly competitive business landscape.

Let’s Chat