Communication is vital to any organization. Fashion designers and brands can leave no room for interpretation to others when it comes to sampling and production. This can go from leaving suppliers to figure out unclear specifications and settling on prices that are too low to missing changes you requested for a particular style.

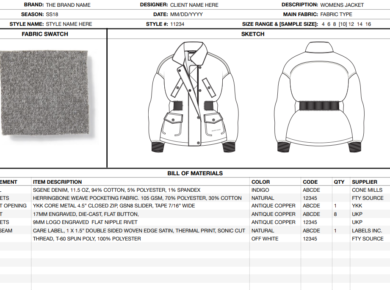

One of the best ways to effectively communicate all of your manufacturing needs to your suppliers is a well-constructed tech pack. Why? Because the tech pack contains all of the details that specify how your garment has to be constructed. This includes flat sketches, measurements, tolerances, materials trims and more.

The tech pack is the ultimate “contract” between the designer and the factory and you should never put the supplier in the position where they have to guess what to do. Here are 5 reasons why tech packs are the ultimate communication tool between fashion brands and manufacturers:

1) The tech pack covers your design details in depth

Your tech pack should tell your factory exactly how to construct your sample and what to include in it. Once this initial sampling process is completed, the tech pack becomes the point of reference for you and your manufacturer.

Let’s say, for example, your factory uses a material or a trim that is not listed or specified. You can go back to your tech pack to check the original specifications and materials for your design, then point out the mistakes to the manufacturer and request the respective changes.

If it’s clear on the tech pack, the factory has to confirm your instructions. And if you’re using Techpacker, these changes can be automatically updated for everyone to see. Meanwhile, all of the edit history is saved if you need to refer back to it in the future.

2) It allows manufacturers to calculate production costs accurately

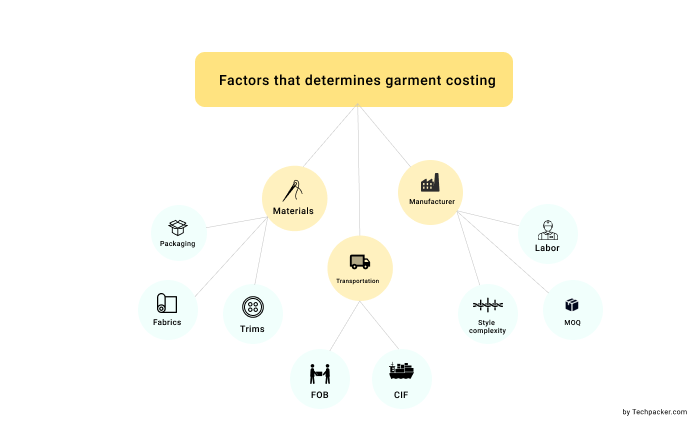

When all the details of the design are communicated and listed clearly in the tech pack, your factory will be able to asses the time and cost with precision. This way, they can get back to you with their estimated costs and times of production, allowing you to negotiate and make adjustments as needed without so much hassle.

Since methods to determine cost may vary among brands and manufacturers, it’s important that the most important elements that affect costing are specified. These include: fabric, trims and packaging, for example.

Take into account that fabric usually accounts for approximately 70% of the total cost. Other factors that weigh in include stitching trims like buttons, zippers, and labels. Packaging for its part, can include carton boxes, poly covers, and hang tags.

The tech pack will also explain the style complexity of the piece. For example, a basic shirt with no pockets will be less expensive to produce than a stylized shirt with patch pockets because it requires less stitching operations.

Order quantity & size specification are also part of the tech pack. MOQ (minimum order quantity) has a significant impact on apparel production costing, the larger the order, the lower the price per item. Similarly, the larger the size of the garment, the more fabric needed to construct it, which in turn will increase the cost.

3) Facilitates team collaboration & communication

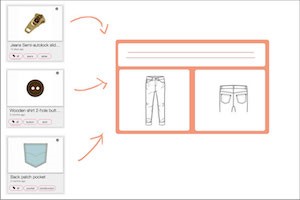

The tech pack goes through the hands of all of the teams that are somehow involved in the creation and production of a garment. It’s safe to say that the tech pack acts as the unifying document between the different roles within your supply chain.

Indeed, since in most cases getting the perfect sample requires more than one round, fit sample reviews and changes have to be well-documented and followed through by everyone.

For instance, a designer might not know the exact measurements for a top, but can only estimate where it will reach in the body and then put the info in a tech pack. Then, the pattern maker can go to the tech pack and to ‘fill in the gap’ and provide more accurate measurements to create a better garment.

If you use software like Techpacker, all these changes are instantly updated in real-time for all of the teams to see. This allows for faster approval rates from designers as a result of a clear tech pack versus emailing back and forth with what needs to be added or changed.

4) They protect suppliers and brands from misunderstandings.

The tech pack serves as a common reference point to resolve problems. It’s common for both sides will blame each other when issues arise. But if the tech packs are accurate and complete then the problem and solution will present themselves within the tech pack.

This is especially true when you are working with suppliers from overseas that may not have a good grasp of English. When you are communicating through email, technical language can get confusing and have spelling mistakes that can lead to misunderstandings.

The clearer your tech pack is, the less you will have to explain over email. Even better if you can eliminate the need to email completely. In any case, with every point and detail neatly organized in the tech pack, it will be easier to use shorter sentences and bullet points to refer to any mistakes or changes you need to request to your manufacturer.

The last thing they want is to go through long paragraphs of text to understand your requirements, especially when there’s no time to spare. Conversely, you’d also want to see the changes as clearly as possible to ensure the design will be error-free.

5) It helps teams identify bottlenecks and communicate their issues

It’s common, and even expected for some type of designs to get ‘stuck’ in one of the stages of product development. Maybe it’s always the same stage or maybe certain types of products tend to take longer in the hands of certain members of your team.

Perhaps a jean with a lot of trims, stitches and details will take longer to represent in flat sketches, as all of the details need to be clearly designed and measured for the rest of the people to understand. Or perhaps your patternmaker is taking longer than usual with a particular style because it has a tricky silhouette.

If one of them is performing slower than usual, it can delay the rest of the teams. This will become evident as the tech pack is being created as some parts won’t be running as smoothly as expected.

How does this affect communication you ask? Without the tech pack it would be very difficult to identify which team or team member is taking longer than usual or is having difficulties. It’s often the case that in difficult situations people don’t reach out for help and try to figure things out on their own, when just a communicating with a colleague or leader could solve the problem.

If you can quickly identify the bottleneck, the head of product development or team members can discuss and come up with a solution for the tricky design in question and help each other out.

What’s more, if you happen to use Techpacker, the new time-tracking allows you to set start and estimated finish dates for tech packs to keep track of how long each part of the tech pack is taking. This provides valuable insights on the speed an efficiency of each stage of the product development process, identifying bottlenecks quickly. You can also generate reports that will help you analyze and optimize production.

About the Author:

Techpaker is a cloud-based software for creating and managing comprehensive tech packs easily and intuitively. It allows you to collaborate with teams and manufacturers for seamless product development to get to market faster than ever before. For more about Techpacker be sure to check out their website and blog.