So, you have weighed the pros and cons, and have decided you are going to manufacture your product offshore. Great choice!

Now what?

Let’s assume (although we could be incorrect), that you have not manufactured offshore before.

We will also assume you do not have any associates that can point you in the right direction, or refer you to a manufacturer.

Our final assumption (We promise) is that your product is a basic item. But, the same procedures can be applied to any product. For your first production run it is better to keep things simple, as you are learning the process.

So where do you start?

As this is a quick start guide, we will look at the quickest way to get your manufacturing going. Just keep in mind that this blog does not preclude some due diligence and common sense on your part.

Research & learn

Firstly, no matter what your product is, do a little bit of research on manufacturing offshore. Every country differs in many ways, so getting a feel of the place is important. Rules, regulations, business environment, culture, stability, and infrastructure for export are useful topics to research.

A quick Google search will bring up many results.

Try to pick some unbiased or neutrally sounding websites. The first two pages of the Google search, should give you a broad idea of the current situation from regulatory requirements to the exchange rate.

Once you have done a little bit of research and have an idea of what you can expect, it’s time to look at actually manufacturing in your chosen country. This seems like a daunting task, but with some planning, it can be done with relative ease.

Utilise online

The quickest way to get started is to use Sourcing Playground and other sourcing websites.

You can either search directly for potential manufacturers, or by posting a project where manufacturers will contact you based on your enquiry and requirements. Either way keep in mind the following.

- Try to stick to verified suppliers. Our verified suppliers, have had an in depth audit done by a third party inspection agency, Asia Quality Focus!

- Narrow down your geographic area within your chosen country or countries. Most countries have planned or unplanned manufacturing clusters or hubs. These are areas that specialise in manufacturing specific products. Subcontractors that these suppliers use are usually located in close proximity as well. This requires some research.

- Be extremely specific as to what you are looking to produce. Give an accurate description, units per order, any required inspection levels or quality levels, required certification for both the manufacturer and the product, country that you importing to, payment terms, and Incoterms.

Check out our guide on posting the best project!

- Ensure your buyer profile is as complete as possible. All sites require registration by buyers, and an accompanying profile. The better your profile, the more seriously manufacturers will take you.

Narrowing down your search

Expect to start getting responses within ten minutes. All these sites will notify manufacturers of a buying lead as soon as it is posted or as soon as you contact a supplier through the site.

Once you get responses, and you will get plenty, you need to assess the responses. You are only looking for certain responses.

- Ignore all responses that look generic or cut and pasted. These are easy to pick out.

- Ignore all responses that mention any terms different to the ones you have requested. For example, if you state you are looking for 500 units, and the response from the manufacturer mentions an MOQ (Minimum Order Quantity) of 1 000 units, ignore them. If you state you pay using a Letter of Credit, and they mention a deposit and balance on delivery, ignore them.

- Ignore all responses that are badly written, such as those with a lot of spelling or grammar mistakes. Remember, you are dealing with someone thousands of kilometers away, so you want good communication.

- Ignore all responses three or four days after placing your lead or contacting a manufacturer. You want timely communication.

To sum this all up. You only want to deal with manufacturers that communicate well and in a timely manner, read your buying lead or enquiry properly, take note of the specifics, and take the time and effort to give a proper response.

Once you have narrowed down the manufacturers to a manageable amount, it is time to start looking at manufacturers that you think are suitable.

Narrow down further

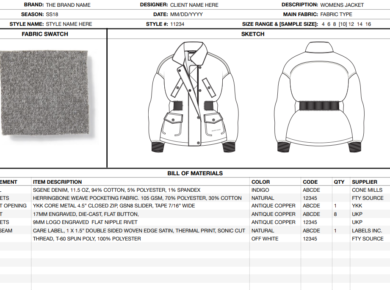

Now you need to send the potential manufacturers information for costing. Ensure this information is complete and laid out in a logical manner, with all specifications.

Also ensure that at this time, you re-confirm all your business terms, such as lead times, sampling requirements, payment terms, Incoterms, inspection requirements, quality requirements, target prices, etc.

We suggest you have at least 5 potential factories at this stage, as some will drop out of the race for various reasons.

As mentioned, some of these manufacturers may have been audited by third parties or even by other customers. Ask if they have been audited and for copies of the reports.

Again, all verified suppliers on Sourcing Playground have been audited, and a copy of the audit is available for all our buyers.

You can also get a third-party inspection agency to do an audit on your behalf. An audit is usually in the range of US $ 250 to US $ 350.

Also ask for factory profiles. A professional factory should have a profile giving information on the factory’s product, machinery, in house peripheral services, customers, and any certification.

Comparing prices

Once prices start coming back, it’s time to compare! Some will be ridiculously high, while some may be very low.

Resist the urge to take the lowest prices. A simple average of the prices you get back, should give a decent idea of the market price you should be paying.

A common tactic to look out for, is manufacturers who give a low price for the first production run, and then hiking this by 20% or more for the next production run.

They will all give you the same reason when this is queried. “You were a new customer, so we gave you a special price.” Their logic is that it will cost you more to find a new supplier, than to pay them extra. However, once you give in to this it will continue.

Don’t be afraid to mention this to manufacturers. Tell them you don’t want the special “new customer” price. You want the real price. This will let them know that you know about this common tactic!

Also keep in mind that there is room to negotiate in all these prices. No manufacturer will give their best price first, in the same way the target price you gave them is not your best price.

When you are costing, remember that the manufacturers price is not the only price you are concerned with. You need to calculate your landed price. This is the price of getting the product to your door, in your local currency. It includes other costs such as shipping, documentation, import duties, tariffs, etc.

We suggest you try to narrow down your suppliers to a primary manufacturer and a back-up manufacturer, in case things go wrong with the primary. It happens.

If your product can be counter sampled, get your primary manufacturer to do so. This might have a cost. Ensure you agree that this cost will be deducted from the cost of the confirmed order, should you decide to go ahead with them.

They may also have samples based on product similar to yours that they can send you.

Once you have confirmed all the prices and you are happy with the counter samples, an order can be placed, and your offshore manufacturing journey has begun.

Good luck and happy sourcing.

Sourcing Playground wants all our buyers to have a great sourcing experience, so feel free to contact us with any questions.