In Part A of this article, I wrote about how suppliers can retain new buyers. I mentioned that, in my experience, most supplier / buyer relationships do not last very long. Usually a few years at the most.

This is more than my personal experience. I have spoken to many buyers over the years who confirm this. In fact, many suppliers will confirm this.

Most buyers are looking for long term, reliable suppliers, that they can do business with for many years. It is costly for a buyer to continually be sourcing new suppliers, both in terms of money and time.

So, the elephant in the room question is, why do buyer / supplier relationships tend to fizzle out over a relatively short period. As this article is geared towards suppliers, how do they keep long term relationships with buyers?

Here’s my advice.

Do not give “new buyer” prices.

Nothing will lose you a buyer faster than this. The scenario is as follows.

A buyer places an order and is happy with the prices. All goes well until the second order, when the prices increase by 15 to 20 percent. When questioned about this, the supplier will tell the buyer, that as they were a new buyer, they were given a special price for their first order. This is extremely common in China. When I approach a potential new Chinese supplier, I specifically state I do not want the “new buyer” price. I want the actual price.

Avoid the commodity price trick.

Simply put, this trick is as follows.

- Assume you are buying a product that consists of four parts. A, B, C and D.

- To keep it simple, lets also to assume each part costs US $25.

- Therefore, the total cost of your product is US $ 100.

- Now let’s pretend the cost of part A increases by 10%.

- The supplier now comes to you, and tells you that the price of the product is now US $ 110.

- Many new, inexperienced buyers will accept this price, without further thought. At first glance it seems logical.

- However, I’m sure many of you can see the trick.

- Only part A increased by 10%, from US $ 25 to US $ 27.50.

- The prices of the other parts remain unchanged.

- So, the new price should be US $ 102,50. Not US $ 110.

This is extremely insulting to a buyer. It assumes they are not very competent.

In fact, it happened to me just this week.

While discussing an order with an Indian apparel supplier, he mentioned that cotton prices had increased by 30%, so the price needed to increase by 30%. As a supplier, think for a moment how ridiculous this is. Cotton is just one input. There are plenty of other inputs in apparel manufacturing, including knitting, wet processing, dry processing, transport, labour, electricity, printing, etc. These did not increase by 30%, so how can the FOB price increase by 30%? An astute buyer will raise this, and the supplier will have no answer.

Mark-ups and open costings.

A good seller will have a fixed profit margin. Let’s say 10%, which is common in my main industry (garments).

So, if a garment’s cost to manufacture is US $ 4.00, the supplier will sell it to me at US $ 4.40.

They should not be marking up the factors of production / production inputs.

Let’s assume my garment also has four parts, like the example used in the commodity price trick.

- On a US $ 4.00 garment, each part has an actual cost of US $1.00.

- Many suppliers will mark up these parts, and still add their profit margin of 10%.

- If they mark up each of the four parts by 10%, and then add their 10% profit margin, they will give me a price of US $ 4.84.

- This is US $ 0.44 more than I should be paying.

On more than one occasion, I have personally found these production inputs marked up by twenty to fifty percent. All this took was a few emails asking for prices of these inputs.

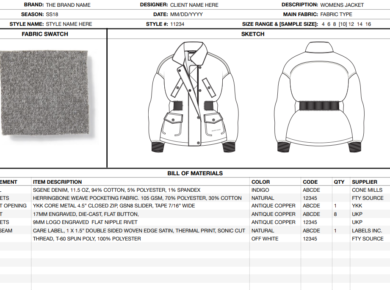

About three years ago, a supplier sent me a fabric swatch card. The price per meter was written on the card, as well as the fabric supplier’s details. I contacted the fabric supplier with an enquiry for the same amount of fabric. With no negotiation, the price I was given was exactly 22% less than my apparel supplier claimed.

This leads me to what are known as open costings.

- A costing simply adds up all the individual items needed to produce the product.

- In all my previous examples, I used 4 individual items, so we’ll stick with this.

- So, the costing consists of 4 items. A, B, C and D. These will be listed along with their individual cost.

- If a supplier shows this costing to a buyer, it is known as an open costing.

Most suppliers are loath to show their buyers their costings. If they are working to a fixed margin, and not marking up inputs, there should be no problem in showing their buyers their costings. Buyers see this as a real sign of good faith and an open and honest relationship.

One issue, is that many suppliers do not actually do formal costings. They “guesstimate”. Obviously, this creates a twofold problem for the supplier. They cannot effectively negotiate, as they do not really know the cost of inputs. Secondly, they are unable to show their buyer the costing. Some suppliers actually pride themselves on their ability to guesstimate. They believe it shows their experience in the industry and their professional ability. To the buyer, it shows the exact opposite.

The bottom line regarding pricing is as follows.

Buyers understand that prices increase. They generally accept this. But they expect all price increases to be backed up by facts, figures, and most importantly honesty.

The above examples, while very common, are dishonest and unethical.

Take responsibility for any supplier related issues and mistakes.

I have mentioned this before in a previous article, but feel it merits mentioning again.

If there is an issue, that can only be attributed to you, as the supplier, or one of your sub-contractors, do not make this the buyer’s problem.

If it will negatively affect the buyer in any way, offer a solution or something else that will improve the buyer’s experience, or at least negate the buyer’s disappointment.

If I had a dollar for every time a supplier has told me that a sub-contractor was late, and there is nothing they can do, so my delivery will be late, I would be rich.

If I gave a dollar for every time a supplier offered a solution, I would be out of pocket about two dollars.

Maybe paying the guilty sub-contractor an extra amount would result in on time delivery, pay it (within reason of course). Think long term, not about the short-term loss of a few hundred dollars. This brings me to my next piece of advice.

Adopt a long-term mindset.

This is very simple. Most suppliers cannot think further than how much money they will have in their pocket tomorrow. This is short sighted and shows a lack of strategic thinking. Think of the amount of profit that you can make servicing a buyer over a ten-year period.

Another personal example. I used to have a denim jeans supplier that I worked with for a few years. One day during a meeting in China, they told me that they could not do my orders. Their reason. A new buyer had come along promising bigger orders, at a higher price. They could have mailed me in this regard, and saved me the trip. But they wanted to show me the purchase order. US $ 500 000 order opposed to my US $ 150 000 one. The supplier totally ignored the fact that over the years, my company had spent over US $ 1 500 000 with them. My orders were not huge, but they added up.

As any prudent buyer, I had back up suppliers ready to start my development. I simply told them how disappointed I was with their attitude, and left.

Six months later, I got a mail from them. The big new buyer, turned out to be a one-time only order, and there were problems with the order, so the relationship terminated. Now they wanted my orders again. They did make a good product, and my CEO wanted to place business with them. I point blankly refused.

A similar scenario played out with a factory in Mauritius not so long ago.

At Sourcing Playground, we believe in trust, transparency, and honesty from all our members. Buyers and suppliers. These are the keys to long term relationships.

Although this article focusses on suppliers, we are not trying to single them out as the cause of relationships failing. Buyers also have similar strategies in dealing with suppliers, that are also extremely damaging to long term relationships.

We will definitely be addressing the buyer side soon.